Our Testing Methodology – Online safety valve testing

Scope of Service

>> Online PSV Testing (Steam, Air, Gas Service)

>> On-Site Valve Diagnostics and performance verification

>> Pre-Shutdown Audits to identify valves needing overhaul

>> In-Situ Overhaul & Minor Repairs where applicable

>> Digital Test Reports with traceable data and compliance tags

Equipment Highlights

Our testers are:

>> Portable, lightweight, and factory calibrated

>> Equipped with precision displacement sensors

>> Backed by data logging systems with real-time graph plotting

>> Capable of testing valves up to 250 bar and above, based on specification

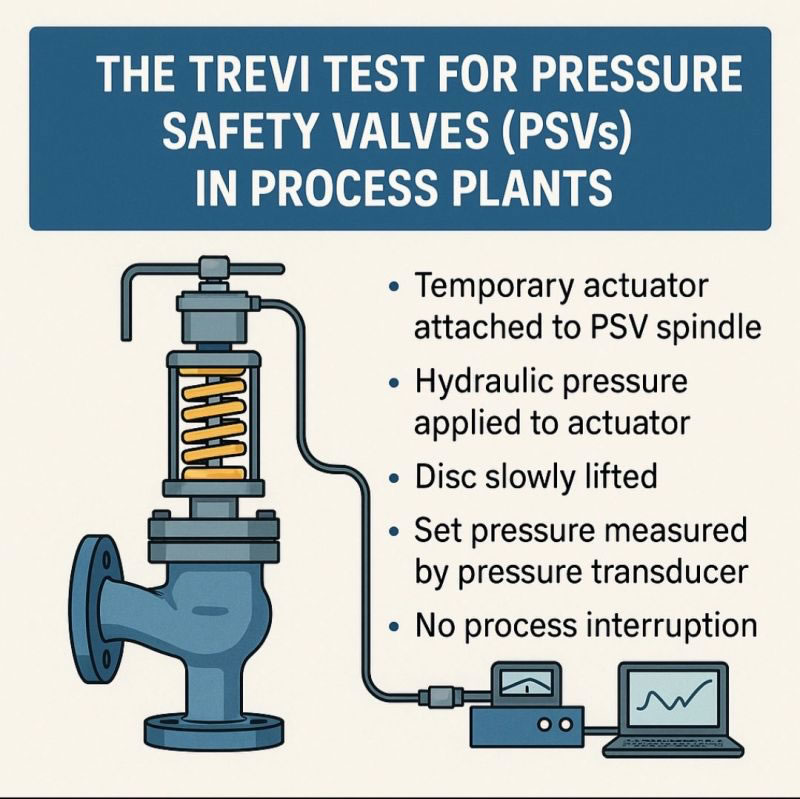

Trevi Test Method (In-situ PSV Testing)

Qualified Experts – Global Standards

Our field technicians are:

>> Factory-trained and certified to operate PSV testing equipment

>> Experienced with valves from all major OEMs including Leser, Bopp & Reuther, Farris, Crosby, and others

>> Committed to HSE standards, with a zero-compromise approach to site safety

Industries Served

>> Thermal & Biomass Power Plants

>> Oil & Gas Facilities

>> Petrochemical & Chemical Plants

>> Pharmaceutical & Food Processing Units

>> Boiler Houses & Pressure Vessel Installations

Deliverables

>> In-situ Test Report with digital graphs

>> Calibration traceability and compliance certification

>> Experts Recommendations for overhauls or replacements

Pop-Up (Set Pressure) Pressure Test

Pop-up testing, also known as PSV pop up or cracking testing, is a specialized method used to verify a valve’s set pressure—the specific pressure level at which it “pops” open to release excess pressure. Below is a quick outline of this process:

© 2025 Created with LankaBiz Holdings